Slide

We Forge Relations

Building enduring relationships and prosperous future with our diverse forging solutions.

Slide

We Forge Relations

Building enduring relationships and prosperous future with our diverse forging solutions.

Slide

We Forge Relations

Building enduring relationships and prosperous future with our diverse forging solutions.

We forge relations

Building enduring relation and prosperous future with our diverse forging solution

We forge relations

Building enduring relation and prosperous future with our diverse forging solution

Our forging solutions offers precision, strength and quality that have laid new benchmark in the industry. Come and discover our diverse forging solutions

About Us

Founded in 2008, Quality Auto Components Private Limited is an ISO 9001:2015 certified company. Today we are proudly recognized as one of the fastest growing forging companies of India. Our growing recognition is a result of our relentless pursuit to provide cutting-edge and quality hot forging solutions to diverse industries. We have employed a team of highly professional and experienced engineers along with scores of workers who continuously work with unwavering passion and determination to render world-class hot forging solutions.

Our Services

We offer forging and valve kit assemblies, heat treatment, machining and surface coating services under one roof

Our company provides a complete metalworking solution, offering forging, heat treatment, machining and surface coating services all in one place. With cutting-edge technology and skilled experts, we ensure quality and precision throughout the entire production process.

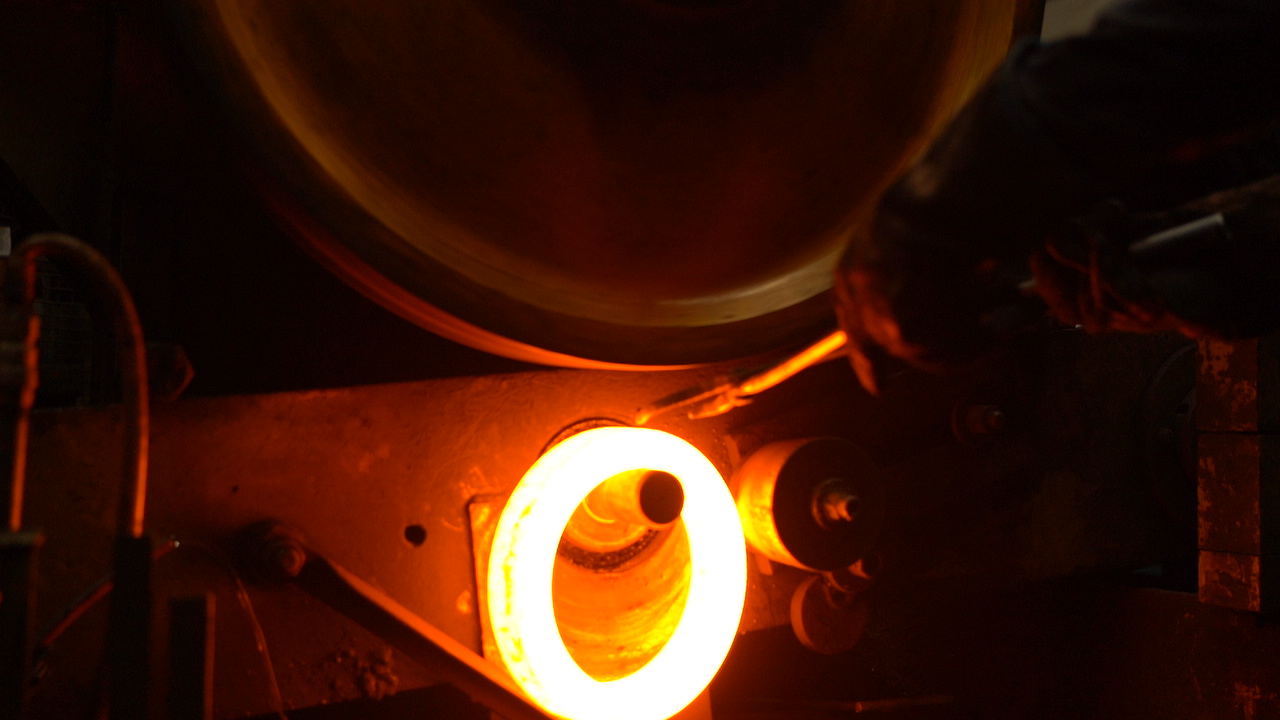

Forging and valve kit assemblies

- Open die forging

- Closed die forging

- Ring Rolling

- Metal Gathering Process

Heat treatment services

- Normalizing

- Hardening

- Tempering

- Isothermal Annealing

- solution annealing

Machining

- Roughing

- CNC Turning

- VMC milling

- Drilling

Surface coating services

- PTFE Coating

- PFA coating

- Xylan surface treatment

- Halar surface treatment

- QPQ & Nitriding

- zinc and manganese phosphating

Materials

Discover premium materials used for offering high-quality forging solutions.

Each material is carefully chosen for its specific properties, ensuring exceptional performance and durability in diverse industrial applications.

01

Alloy Steels

- AISI 4130

- AISI 4140

- AISI 4340

- AISI 4340AQ

- AISI 1045

- A 182 A105

02

Carbon Steels

- AISI 1018

- 1045

- 1040

- C55

- EN9

- AISI 4140

03

Stainless steel

- AISI 304

- 316L 304L

- 17-4PH

- 410

- AISI 321

- AISI 421

why choose us

When you choose us as a forging partner, you enjoy several unique benefits and advantages that will eventually help your company in propelling its growth and creating a financially viable future. These unique benefits set us apart and has given us the status as an emerging leader in the forging industry.

- 15 years of experience & counting

- Advanced & cutting-edge technology

- Affordable costing

- End-to-end forging solution

- Growing Industry recognition

- Customer centric approach

Our Future Plan

- API Certification Q1 & API 20C

- Increasing forging capacity by 500 MT per month

- Increasing Capacity of forging & heat treatment by 500 MT to 1000 MT.

- Adding more CNC, VMC, VTL & HMC machines

Our Happy & Trusted Customers